Services

Design

Great parts don't just happen; they are engineered for success from the very beginning. The Design service at Pure Shape 3D is where we partner with you to bring your vision to life, even if you don't have a design file to start with. We can help you create custom CAD files for simple, functional items like storage solutions, holders, and mounts. Using our preferred tool, FreeCAD, we then perform essential tasks like manipulating geometry for better structural integrity, combining separate pieces for efficiency, and conducting the detailed prep work that guarantees a flawless print every time.

This foundational work is what unlocks the true potential of 3D printing: repeatability. By perfecting the design and setup process, we create a reliable and cost-effective solution that can outperform traditional methods for small-batch runs and complex parts. We handle everything from initial concept to final calibration, ensuring your vision is translated into a physical object with precision. We are skilled in mechanical design for 3D printing, but for applications requiring formal engineering certification, we recommend involving a licensed professional to provide that final sign-off. Our role is to ensure the part is manufactured to the highest possible standard, whether we started from your sketch or your solid model.

Printing

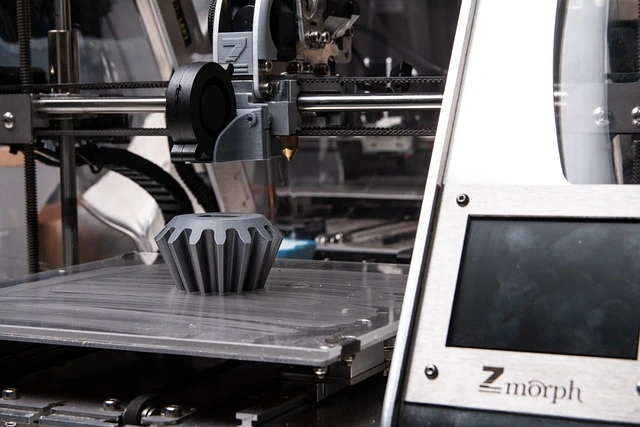

At Pure Shape 3D, our printing philosophy is guided by a single, crucial rule of thumb: slower is better. While it may seem counterintuitive in a fast-paced world, we deliberately prioritize quality over speed. We don't just crank up the velocity to rush parts out the door. Instead, our process involves finding the optimal speed for your specific part geometry and chosen material. This meticulous approach ensures that each layer has ample time to bond with the last, resulting in a final product that is significantly stronger, more dimensionally accurate, and has a superior surface finish.

The science backs this up: numerous studies have shown that slower print speeds directly correlate with increased part quality and tensile strength. For us, this isn't just theory; it's a commitment to excellence. We understand that the parts we print are often critical components, not just disposable models. By investing the extra time required for a slower, more controlled print, we are investing in the reliability and performance of your final product. This dedication to process is what allows us to deliver parts you can trust to perform under stress, fit together perfectly, and look professional.

Post-Processing

The final mile of manufacturing is often what makes the biggest impression, and that's where our post-processing services come in. A 3D printed part has immense potential, but its true form is unlocked through expert finishing. From vapor smoothing that gives ABS parts a glossy, injection-molded look to light sanding that prepares a surface for a flawless paint job, post-processing is the key to achieving a premium result. We offer these services to ensure your product has the refined appeal and professional quality it deserves.

Pure Shape 3D is your one-stop shop for taking your project across the finish line. Our post-processing capabilities are designed to save you time and deliver a superior final product. This includes vapor smoothing for a perfect finish, light sanding for tactile smoothness, and painting for a custom, durable coating. Furthermore, we can assemble multi-part prints and install any necessary hardware, providing you with a complete, functional unit. Trust us to handle these critical final steps, ensuring the parts you receive are not just printed, but are fully prepared for their intended application.

3D Scanning*

Have a physical object but need a digital file? Pure Shape 3D provides professional 3D scanning services to bridge that gap. We specialize in capturing real-world objects and transforming them into precise CAD models, opening the door to endless possibilities for modification, replication, and analysis. This is the perfect solution for reverse engineering obsolete parts, creating custom mounts for existing equipment, or developing a product based on a physical prototype. Our equipment is adept at handling a wide range of scales, accurately capturing everything from small, detailed items to larger objects under 4 feet tall.

We understand that some objects are too large, too heavy, or too important to move, which is why we bring our scanning studio to you. We offer on-site scanning services throughout the Grand Rapids, Michigan area, within a 50-mile radius of our base. This is one of our two core services that can be performed as a standalone solution—simply providing you with the CAD file—or as the first step in a larger project. By combining scanning with our design and printing capabilities, we can take a physical object, digitize it, modify it, and print a new, improved version, offering you a complete and seamless manufacturing solution.

Reverse Engineering*

Leveraged alongside our 3D scanning capabilities, our reverse engineering service offers a powerful solution for modernizing and improving existing products. This process allows us to take a previously designed assembly, deconstruct it digitally, and generate new, manufacturable 3D printed parts. It's the ideal service for clients with legacy components that are no longer in production, worn-out parts for which replacements are unavailable, or for simply creating a digital backup of a critical physical asset. We give you the flexibility to move from an obsolete physical part to a brand new, functional one.

The true power of reverse engineering for additive manufacturing lies in redesigning for the future. We don't just replicate; we optimize. In many cases, we can consolidate multiple components of an original assembly into a single, complex "print-in-place" part. This innovation reduces assembly time, eliminates potential points of failure, and creates a more robust final product that would be impossible or prohibitively expensive to achieve with traditional manufacturing methods. Our reverse engineering service is about more than just making copies; it's about using modern technology to make your parts better, stronger, and more efficient than the original.

Emergency Part Replacement*

When a critical piece of equipment fails, the pressure to get back online is immense. The traditional model of ordering replacement parts—often from overseas with high costs and long lead times—can cripple a project's profitability. Pure Shape 3D offers a modern, agile alternative with our emergency part replacement service. We specialize in quickly manufacturing the parts you need to get your machinery up and running again. Whether you require a short-term patch or a long-term replacement, our rapid, on-demand printing provides a powerful solution to minimize costly downtime.

Our primary focus is on legacy machines that are out of warranty and for which spare parts are no longer available. For these assets, 3D printing isn't just an option; it's the only option for keeping them operational. We can act as your strategic partner, creating a digital and physical inventory of critical components to prevent future breakdowns. For newer machines under warranty, we can provide a temporary fix to bridge the gap while you wait for the official part, helping you avoid the catastrophic costs of a shutdown. We advise that the OEM part be installed permanently to maintain warranty compliance, but our service ensures that you don't lose valuable production time in the meantime.

*These services are not available until April 6th, 2026.