The Future . . .

Printing Now

In a world moving at breakneck speed, the gap between imagination and reality is finally closing. Traditional manufacturing, with its long lead times and rigid processes, can no longer keep pace with innovation. Additive manufacturing is the answer, a technology that builds the future layer by layer, on demand. Pure Shape 3D is your gateway to this new era, where we can turn your idea into a functional prototype in a fraction of the time. Let's stop waiting for the future and start building it.

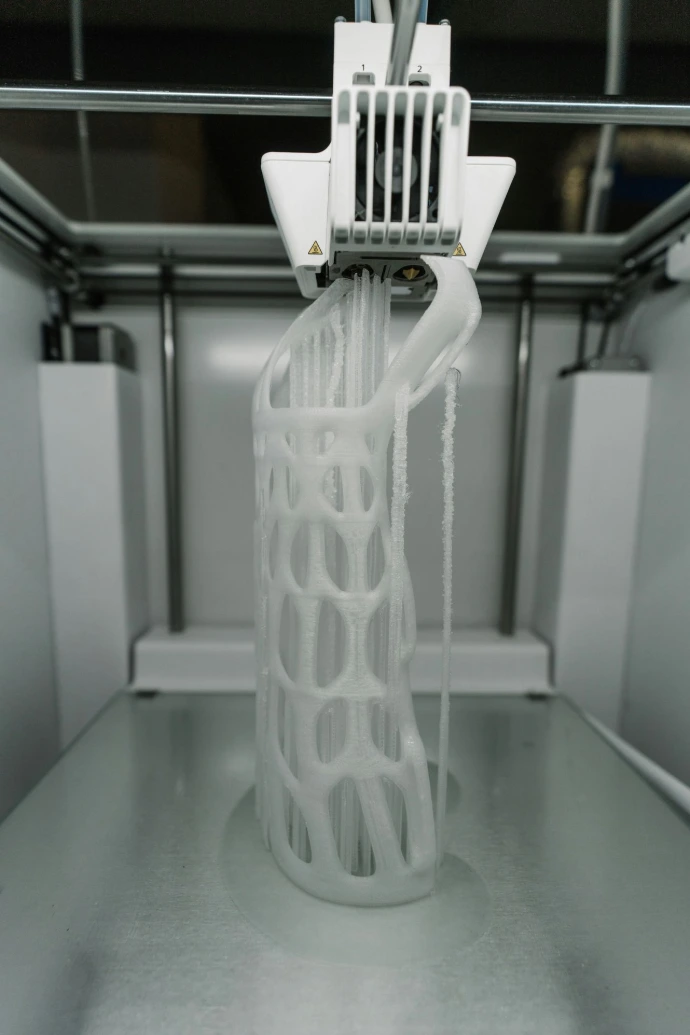

FDM Printing

At Pure Shape 3D, we specialize in high-quality Fused Deposition Modeling (FDM) printing, transforming your digital designs into tangible, robust objects. Our process is engineered for versatility, allowing us to work with a vast spectrum of materials—from standard PLA and ABS for general prototyping to advanced, engineering-grade filaments like PETG, ASA, and carbon fiber-reinforced composites. This material flexibility ensures that your final product isn't just a model, but a functional part built to withstand real-world testing, stress, and environmental demands.

The core of our business is built around the advanced capabilities of our two Vision Miner 22 IDEX printers. These machines are engineered for professional-grade production, featuring Independent Dual Extruders that unlock game-changing possibilities. This technology allows us to print with two different materials or colors simultaneously—perfect for complex parts requiring integrated flexible seals or soluble supports for intricate, otherwise impossible geometries. Furthermore, the IDEX system can print two identical parts at once, effectively doubling our production speed for batch runs and ensuring your projects are delivered with maximum efficiency.

To complement our high-efficiency production line, we also operate a Qidi Max4. This powerhouse of a printer provides us with an enormous 390 x 390 x 340 mm build volume, ideal for creating large, single-piece parts, complex assemblies, or producing multiple smaller components in a single, efficient batch. This combination of specialized dual-extrusion and large-format printing means we are equipped to handle a diverse range of projects, from single, intricate prototypes to small-batch production runs. While our current focus is on mastering the art and science of FDM, we are always looking toward the future of additive manufacturing and plan to expand our capabilities soon.

Materials

From standard prototyping plastics to advanced high-performance polymers, Pure Shape 3D offers a comprehensive range of materials to bring your project to life. Our core inventory is strategically sourced from leading US manufacturers like 3DXTech, ensuring you receive reliable, high-quality filaments with dependable supply chains. This partnership allows us to provide a robust selection of everything from easy-to-print PLA and durable ABS to engineering-grade materials like carbon fiber composites and flame-retardant polymers, giving you confidence in both the material's origin and its performance.

We go beyond simply offering a list of options; we act as your material consultants. The success of any 3D printed part hinges on selecting the right material for the application, whether it requires flexibility, high temperature resistance, chemical inertness, or ultimate strength. Our expertise allows us to guide you to the perfect choice, balancing performance requirements with budget and printability. While we prioritize US-sourced materials, our deep knowledge of the FDM landscape means we are also fully capable of sourcing and working with a wide array of specialty filaments from global suppliers to meet the most demanding and unique project specifications. To explore the full spectrum of what's possible, we invite you to visit our detailed Materials page.

Small-Batch Orders

Pure Shape 3D is purpose-built for small-batch orders, providing a vital service for those who fall between the gap of one-off prototypes and mass production. We recognize that not every project requires thousands of parts, and traditional manufacturing methods often make small runs prohibitively expensive and slow. Our FDM workflow is specifically optimized for agility, allowing us to produce high-quality parts in quantities from a single piece up to 200 units efficiently. This makes professional-grade manufacturing accessible to startups, engineers developing new products, and businesses needing a limited run of custom components.

Our small-batch capability means you get the benefits of production-quality parts without the massive upfront tooling costs and long lead times of traditional methods. We can iterate on designs with you and produce updated versions in a matter of days, not weeks. While our standard focus is on orders under 200 parts, our scalable production capacity allows us to accommodate larger runs based on project demand and lead-time requirements. Whether you need 10 parts for market testing or 150 for a limited product launch, Pure Shape 3D is your agile manufacturing partner, ready to deliver quality parts on your schedule.

Quality

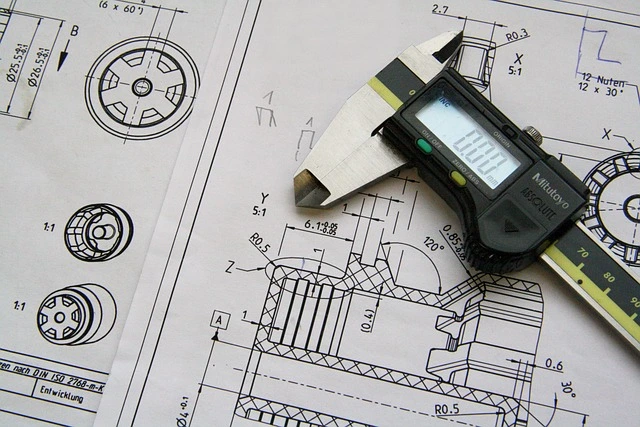

At Pure Shape 3D, quality isn't just a goal; it's the foundation of our entire process. We operate on a simple, non-negotiable principle: if a part isn't good enough for our own standards, we will never consider it good enough for you. This means every single item that leaves our facility undergoes a rigorous quality assurance check. We don't just print and ship; we meticulously inspect each part to ensure it meets the specified dimensions, tolerances, and structural integrity required for its application.

We believe you deserve the highest quality, every single time. This commitment drives us to go above and beyond, from fine-tuning printer settings for each specific material to performing post-processing steps that enhance the final product's finish and function. We understand that in engineering and product development, precision is paramount. A part that is even slightly out of tolerance can compromise an entire assembly. That's why we guarantee dimensional accuracy and hold ourselves to the tightest possible standards, ensuring the parts you receive are ready to perform as designed right out of the box.

Material Sourcing

At Pure Shape 3D, we are committed to sourcing our materials from the United States as much as possible, a decision that benefits both our clients and our national economy. By partnering with leading American suppliers like 3DXTech, we not only support domestic manufacturing but also create tangible value for you. Sourcing from local and national suppliers reduces complex international shipping costs and logistical delays, allowing us to offer more competitive pricing and faster turnaround times on your projects. It’s a strategic choice that results in higher quality parts at a better value.

We believe in investing in the strength and innovation of the American economy. Every spool of filament we purchase from a US-based company helps sustain skilled jobs and supports a robust supply chain right here at home. This commitment is more than just a business decision; it’s a core part of our identity. When you choose Pure Shape 3D, you are not only getting expertly printed parts, but you are also partnering with a company that prioritizes American quality and economic resilience. We are proud to contribute to an ecosystem that delivers excellence from coast to coast.

Personal Service

At Pure Shape 3D, we redefine customer service by making it a core part of our manufacturing process. We believe that every person who has a hand in your product should be involved in problem resolution. When you work with us, you're not dealing with a distant support ticket system; you're communicating directly with the technicians and engineers operating the printers and handling your files. This integrated approach means the person who understands the technical nuances of your project is the same person helping you find a solution.

Eliminating the distance between a problem and its solution is paramount to an efficient and successful manufacturing process. We've seen how frustrating it can be when messages get lost between departments, leading to delays and miscommunication. By ensuring the entire team is aligned and accessible, we can address challenges, iterate on designs, and resolve issues in real-time. This hands-on, collaborative model ensures that your project moves forward smoothly and that the final product precisely meets your expectations, without the bureaucratic headaches you might find elsewhere.